Wuxi Tonglike Technology Co., Ltd.

professional company engaged in weightless Feeder.

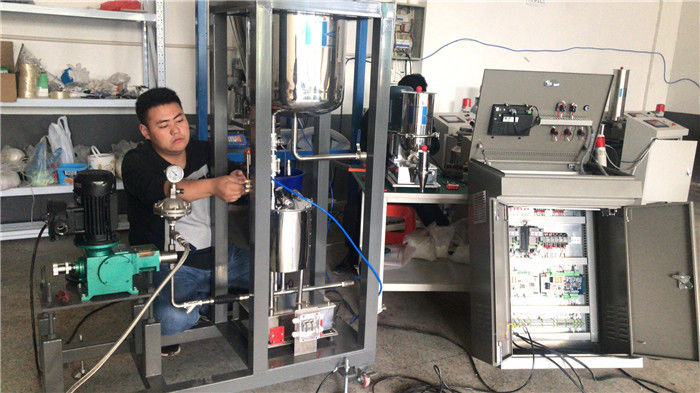

High Speed Powder Screw Feeder , Mini Screw Feeder Simple Operation

Product Details:

| Place of Origin: | WuXi , China |

| Brand Name: | Wuxi Tonglike |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden case |

| Delivery Time: | 30 Days |

| Payment Terms: | Western Union, L/C, T/T, D/A, D/P, MoneyGram |

| Supply Ability: | 30 Sets Per Month |

| Material: | 304 Stainless Steel (Food Grade) | Type: | Screw Conveyor |

|---|---|---|---|

| Structure: | Horizontal Conveyor | Feeding Range: | Pellet, Free Flowing Powder, Fibrous Materials |

| Material Feature: | Heat Resistant | Condition: | New |

| Highlight: | powder screw feeder,dosing screw feeder |

||

Micro Screw Feeder

Principle and Operation

Product is directed into a variable speed metering screw, which runs completely and evenly filled and is linked to an electronic feed back drive ensuring accurate speed holding under all load conditions. Resulting in material being metered out at a constant volume of between ±1% to ± 2%.

Choice of Feeder

The selection of the correct type of feeder from the extensive Rospen range is determined primarily by the type and specification of the material to be handled. Both single and twin, screw feeders are equally as efficient, with the single screw mechanically simpler and therefore, more economical and is the prime choice where practical. Both units share the following features and benefits

- Large inlet eliminates material bridging.

- Tapered Conditioning Chamber de-aerates fluidising powders or livens cohesive materials ensuring screw runs completely and evenly filled.

- Suitable for use with very fine to coarse, or fibrous, particulate products.

- Easily removable front cover provides a safe and quick access for cleaning.

- Instant release of feed screw without shaft seal disturbance.

- Ideally suited to industries that require rapid clean down and product changes.

Product Feature

- PLC control system

- Two sealing types:sack closer and heat sealer

- Three-sensor structure to keep more stable

- Can fill with nitrogen or carbon dioxide to have vacuum packing

- The sack closer has atuo oil-supply system

- Auto sewing

- Auto thread cutting with infrared sensor

- Auto lifting conveyor

- Easy installation

Our Value-added Service Package

1. Installation Services: During the period of installation and debugging, we shall offer training about effective operation.

2. Technical Services: Our company has been devoting ourselves into offering custom transforming projects for our worldwide clients in the field of medical, chemical engineering, plastics, rubber industries etc.

We can assist our clients to solve all kind of technical problems with our capable technician team, and we own adequate experience for production line transformation as well as formula feeding arrangement.

3. Warranty Services: We offer free after sale service except the engineers' traveling expense for any quality problem occurs during our 12 months warranty period.

Service

1) OEM services provided

2) Excellent quality assurance

3) Fast delivery

4) Worldwide dealer or agent needed

FAQ

Q1: How can I find a loss in weight feeder machine model suitable for my product?

According to the material you are going to use.

Q2: May I know the delivery time?

Delivery will be within 20 days .

Q3: What type of payment do you have available?

We accept TT payment for offline orders.

Q4: How does your factory control the quality?

We are controlling the quality from beginning to the end.

Contact Person: Mr. Paul Alison

Tel: +86-18114858555

Fax: 86-0510-83758484